Products

Explore Our Steel Products Collection

Welcome to our Steel Products section, where strength, durability, and versatility converge to redefine the possibilities in construction, manufacturing, and infrastructure.

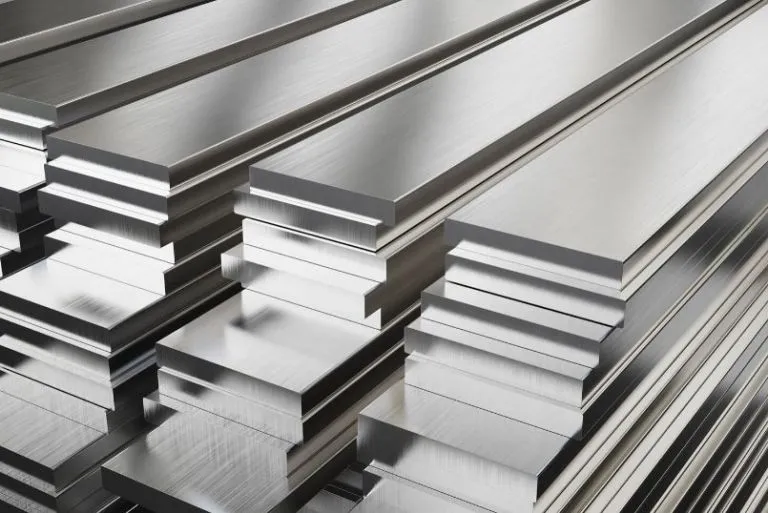

Alloy Steel

Alloy steel is steel that has elements other than carbon added in sufficient quantities to give the metal-specific qualities. Manganese, vanadium, chromium, nickel, and tungsten are some of the alloying elements. It’s usually done to improve the material’s strength, hardness, toughness, abrasion, and wear resistance, as well as its electrical and magnetic properties.

Stainless Steel

This type of metal is defined as steel that resists oxidation and corroding from corrosive media when heat-treated and polished directly. It’s also known as rust-free steel because it includes at least 11% chromium, which prevents iron from rusting while also providing heat resistance.

Our Aluminum Products Showcase

Our curated selection of aluminum products represents a commitment to excellence, innovation, and the transformative power of this lightweight and corrosion-resistant metal.

Aluminum

Aluminum is a type of metal with the atomic number 13 and the symbol Al. It’s a light, bluish-white metal with a specific gravity of 2.7 and a melting point of 658 degrees Celsius. The metal’s density is around one-third that of steel, making it less dense than other popular metals. The metal would be weak and mushy in its pure state for most applications, but when mixed with minute amounts of other alloys, it becomes strong and stiff.

Aluminum Foil

Aluminium foil is a thin sheet with a thickness of less than 0.2mm, it is produced by rolling sheet ingots cast from molten billet aluminum, then re-rolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold rolling. Most of the aluminum foil paper is shiny on one side and matte on the other. It is mainly used for packaging food, medicine, cosmetics, and other chemical products.

Galvanized Products Showcase

Our Galvanized Products section, where durability meets corrosion resistance to redefine the standards of reliability in construction, manufacturing, and various industrial applications.

Galvanized Wire

Hot-dipped galvanized mild steel line wire, for tensioning and straining wire netting, chain link fencing, stock fences and plastic mesh and netting. The steel line wire should be tensioned between the metal or wooden fencing posts or stakes (square sawn or machine rounded treated timber or hardwood) using a tensioning tool or ratchet and secured using galvanised U-nails or clips. Once the wire is under tension, the mesh or chain link fencing can be clipped using nylon ties or hog-ring clips.

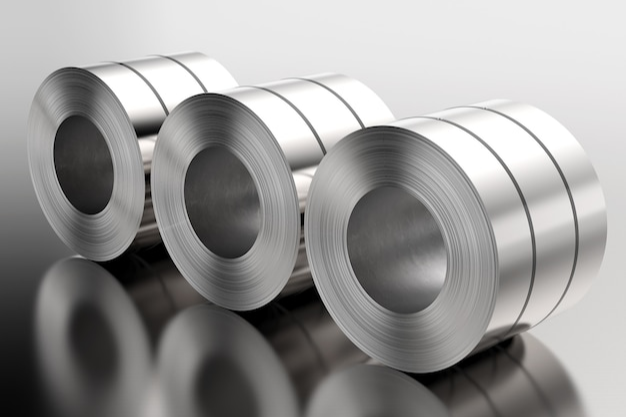

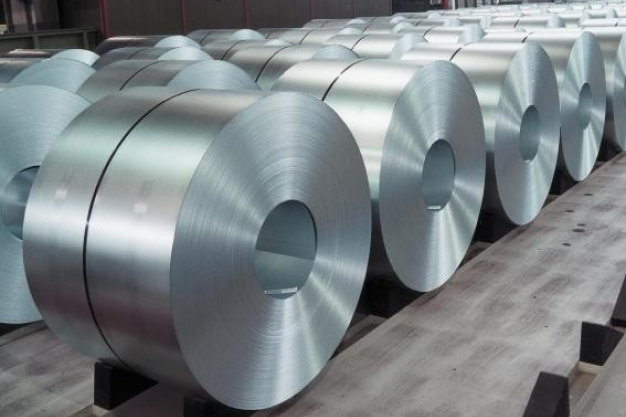

Galvanized Coil

Galvanized coil are mainly applies in some professions, such as constructions. For the constructions, it mainly used as roofs of some industrial, residential constructions to preventing from corrosion. For the light industry, it used to produce outer cover of electrical appliances, chimney, kitchen utensil and corrosion-proved parts of automobiles. And it is also used as storage and transport in farming, animal husbandry, fishery area.

Copper

Copper is a chemical element with the atomic number 29 and the symbol Cu. It is a reddish-brown metal that is soft, malleable, and ductile. It has an 8.9 specific gravity and a melting point of 1083°C. Copper is not found in its purest form underground. It has excellent electrical conductivity. Cast, forged, rolled, and pulled into wires are all options for the metal.

Iron

Iron is a chemical element with the symbol Fe for its symbol. It belongs to the periodic table’s first transition series and group 8. Even though it was a very old metal during the “Iron Age,” it still has a lot of modern applications. Iron is the most widely used and least expensive metal on the planet.

Timeless appeal combined with enduring quality

At EZY Metals Trading, the timeless allure of brass and bronze meets enduring quality in every meticulously crafted product. Our dedication to excellence ensures that each piece not only exudes a classic aesthetic but also boasts the lasting durability inherent to these exceptional metals.

Brass and Bronze

Brass is the most widely used copper and zinc alloy in today’s globe. Various varieties of brass are available, depending on the copper-to-zinc ratio. Brass is more durable than copper, although it has less thermal and electrical conductivity.

Bronze is a term used to describe copper and tin alloys. 75 to 95 percent copper and 5 to 25 percent tin are the most useful proportions. These metals are rather hard, have a high resistance to surface wear, and can be easily molded or rolled into wires, rods, and sheets.

Explore the exceptional in every element.

At EZY Metals Trading, explore the elegance of endurance with our zinc, magnesium and cobalt creations. Our commitment to excellence extends to every element, ensuring that each one not only stands out for its unique properties

Cobalt, Magnesium and Zinc

The chemical element cobalt has the symbol Co and the atomic number 27. Its physical properties are identical to those of iron, with the addition of nickel. Cobalt is a strong, shiny, silvery-gray metal that is created via reductive smelting.

Magnesium, usually known as Mg, is a chemical element with the atomic number 12 and the symbol Mg. It’s a glossy gray solid with a lot of physical and chemical features in common. They also accept a high polish under the buffering wheel.

Zinc is a chemical element with the symbol Zn and the atomic number 30. When no oxidation occurs, zinc is a brittle metal with a silver-brown color. Zinc has a specific gravity of 7.1 and a melting point of 420°C. These types of metals are used to cover steel sheets to make galvanized iron because of their strong resistance to air corrosion.

Alloy Steel

Alloy steel is steel that has elements other than carbon added in sufficient quantities to give the metal-specific qualities. Manganese, vanadium, chromium, nickel, and tungsten are some of the alloying elements. It’s usually done to improve the material’s strength, hardness, toughness, abrasion, and wear resistance, as well as its electrical and magnetic properties.

Stainless Steel

This type of metal is defined as steel that resists oxidation and corroding from corrosive media when heat-treated and polished directly. It’s also known as rust-free steel because it includes at least 11% chromium, which prevents iron from rusting while also providing heat resistance.

Iron

Iron is a chemical element with the symbol Fe for its symbol. It belongs to the periodic table’s first transition series and group 8. Even though it was a very old metal during the “Iron Age,” it still has a lot of modern applications. Iron is the most widely used and least expensive metal on the planet.

Aluminum

Aluminum is a type of metal with the atomic number 13 and the symbol Al. It’s a light, bluish-white metal with a specific gravity of 2.7 and a melting point of 658 degrees Celsius. The metal’s density is around one-third that of steel, making it less dense than other popular metals. The metal would be weak and mushy in its pure state for most applications, but when mixed with minute amounts of other alloys, it becomes strong and stiff.

Copper

Copper is a chemical element with the atomic number 29 and the symbol Cu. It is a reddish-brown metal that is soft, malleable, and ductile. It has an 8.9 specific gravity and a melting point of 1083°C. Copper is not found in its purest form underground. It has excellent electrical conductivity. Cast, forged, rolled, and pulled into wires are all options for the metal.

Brass

Brass is the most widely used copper and zinc alloy in today’s globe. Various varieties of brass are available, depending on the copper-to-zinc ratio. The qualities of brass can be drastically altered by introducing small amounts of other elements, which can be mechanical, electrical, or chemical. Brass is more durable than copper, although it has less thermal and electrical conductivity.

Bronze

Bronze is a term used to describe copper and tin alloys. 75 to 95 percent copper and 5 to 25 percent tin are the most useful proportions. These metals are rather hard, have a high resistance to surface wear, and can be easily molded or rolled into wires, rods, and sheets. Bronzes are superior to brasses because they have better corrosion resistance.

Cobalt

The chemical element cobalt has the symbol Co and the atomic number 27. Its physical properties are identical to those of iron, with the addition of nickel. Cobalt is a strong, shiny, silvery-gray metal that is created via reductive smelting. Cobalt can be found in plants and animals, as well as in the air, water, soil, and rocks. Wind-blown dust or rainwater can also wash away cobalt-rich soil and rock, allowing them to enter other habitats.

Magnesium

Magnesium, usually known as Mg, is a chemical element with the atomic number 12 and the symbol Mg. It’s a glossy gray solid with a lot of physical and chemical features in common. This is the lightest metal, with a cast metal tensile strength of 910 kg/cm2. These kinds of metals are tougher than aluminum and can be easily machined. They also accept a high polish under the buffering wheel.

Zinc

Zinc is a chemical element with the symbol Zn and the atomic number 30. When no oxidation occurs, zinc is a brittle metal with a silver-brown color. Zinc has a specific gravity of 7.1 and a melting point of 420°C. These types of metals are used to cover steel sheets to make galvanized iron because of their strong resistance to air corrosion.